Water Pumping – Hydro-powered Pump Systems

Background

The use of hydro-electricity is a sensible self-sufficient solution for pumping water from great depths considering the high energy requirements and the frequent lack of electrification in remote areas. Due to topographical differences in altitude, there also exist great hydroelectric potential which, until now, has only been exploited by small, individual hydroelectric plants.

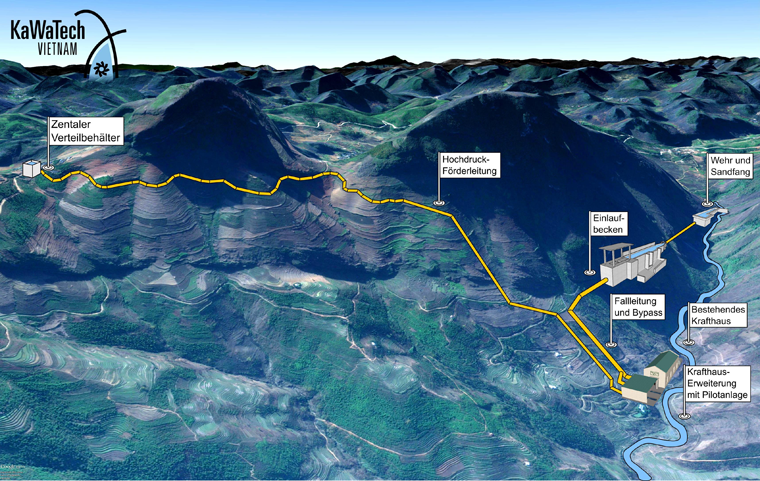

Schematic illustration of the main components of the Seo Ho High-Pressure Plant and the new water pumping System

One of these power plants is the Seo Ho High-Pressure Plant constructed in the 1990s and equipped with 2 Pelton turbines. For its operation, the powerhouse is supplied with feed water from the Seo Ho River through a weir with an intake structure, a sand trap, a headrace channel, an intake pool and a penstock. Due to the distinctive rainy and dry seasons, the Seo Ho River is characterized by strong, temporal runoff fluctuations. This made the construction of the turbines, whose installed capacity of approx. 700 kW was, as usual, targeted at the comparatively high runoffs during the rainy and/or transitory season, more difficult. As a result, economic operation cannot be permanently guaranteed in times of low water supply due to the reduced performance potential and falling turbine efficiency in the lower partial-load range and in spite of the low labor costs typical of emerging countries. In the dry season, this results in a weeks-long downtime for the plant, while the population in higher-lying settlements simultaneously suffers from severe water scarcity.

The unused residual water can however be efficiently used with machine units specially designed for these conditions to generate the operating power for pumping water. Against this backdrop, a concept was developed and implemented in the form of a pilot plant that envisages the addition of a mechanically powered pumping system to the Seo Ho Hydroelectric Plant. Many years' experience regarding the conception of innovative machine technology, which was gained during previous BMBF-sponsored collaborative projects in Indonesia, entered into the above project.

The pump system comprises two simultaneously operated pump modules which can be described as a mechanically coupled unit of a "pump as turbine" (PAT) and a feed pump. "Pumps as turbines" are used as power units for high-pressure pumps, because inversely operated pumps are a cost-effective alternative to water turbines. On the whole, this design stands out through high robustness and low operation and maintenance costs. The innovation of this concept lies in the first-time design of such a module for high-pressure conditions and in the hydraulic and operational linkage to an existing hydroelectric plant.

Objective

Building on the achievements of the KaWaTech project, there are plans for specialist support for the reference plant in the initial operational phase, comprehensive validation as well as, if necessary, more far-reaching operational optimization of the machine technology in particular and the pumping concept in general. An aspect crucial to successfully implementing this project is continuous cooperation with the operator and with local specialists to enable comprehensive knowledge sharing between the partners from both countries.