Previous Findings

Through the R&D activities of the "KaWaTech" collaborative project (Funding Code: 02WCL1291A, Duration: September 2013 to August 2016), the following principal results, which form the basis for further work within the "KaWaTech Solutions" project, were delivered, among other things:

Physiographical Experiments

In-depth testing of physiographical conditions within the project region using, among other things, speleological explorations and paleontological studies, tracer studies, runoff (underground and aboveground) and precipitation measurements as well as through hydro-chemical and microbial monitoring.

Speleological explorations to evaluate aquiferous caves as potential implementation locations for innovative water pumping systems (left), tracer studies for analyzing flow paths (right)

Runoff measurements underground (using level probes, left) and on the surface (using ultrasound Doppler method, right)

Execution of multi-week measurement campaigns to evaluate enzyme activities of E. coli (left), paleontological studies for climate reconstruction (right)

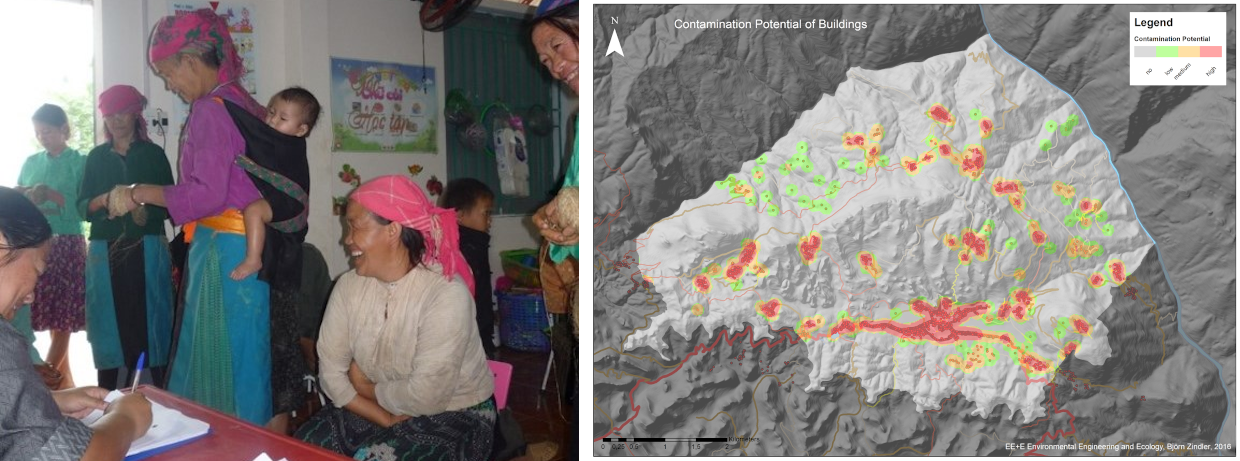

Socio-cultural Surveys and Provision of a GIS Database

Characterization of societal parameters with regards to sustainable water pumping and distribution in the model region, capturing of settlement structure, land use, etc. as well as the creation of a GIS-based planning foundation.

Conduct of a number of surveys regarding local problems in the water sector (left), compiled map of contamination potential (right)

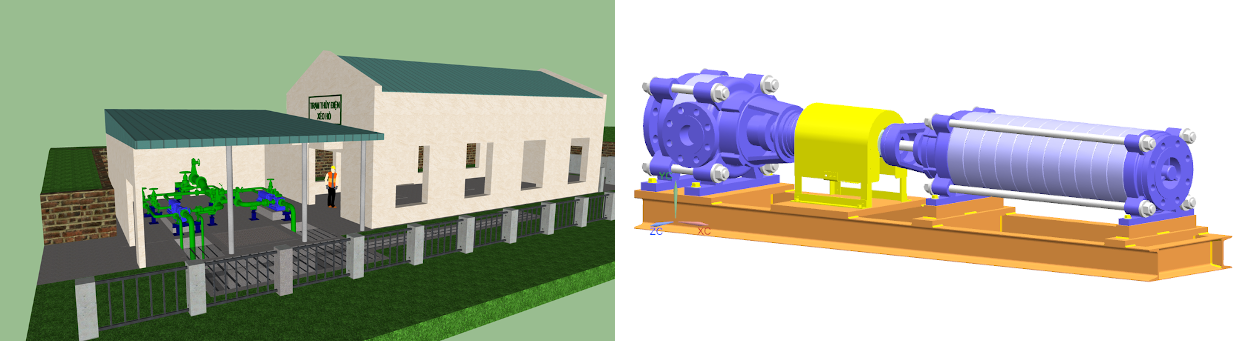

Innovative Water Pumping Technologies (Pumping Concept 1)

Implementation of a technical solution for adding a hydro-powered water pumping system to existing hydroelectric plants in order to utilize low quantities of water, which cannot be efficiently used to power turbines, as well as the construction of a reference plant with a pumping capacity of up to 1.5 million litres per day.

CAD model of a hydro-powered pump system as a bypass solution for existing hydroelectric plants in order to pump water using residual amounts of water (left), CAD model of a pump module (manufacturer: KSB AG; PAT: MTC 65/2 6.1; pump: MTC 50/12 4.1) (right)

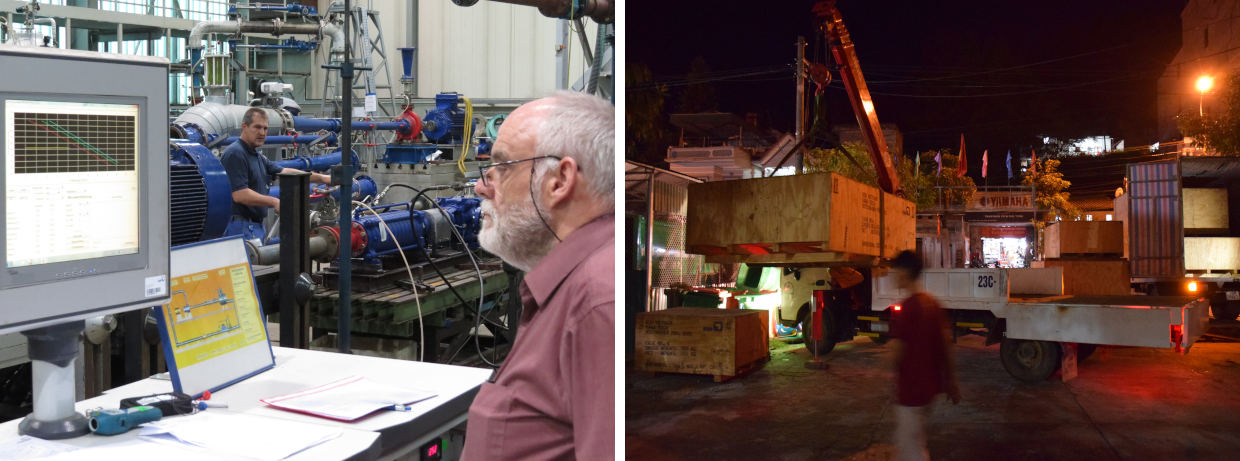

Validation of machinery at the research test field of KSB AG (left), arrival of the modules and pipe segments in Dong Van City (right)

Assembly and alignment of the pump system in close cooperation with the future operators

Hydroabrasive damage on the weir (left), refurbishment of the concrete structure of the weir including optimization of the intake structure (right)

Removal of root growth from the head race (left) and partial reconstruction of the channel at critical sections (right)

Renovation of the concrete structures and hydraulic optimization of the intake basin using components (deflectors, stilling basins, rectifier course, etc. to reduce the turbulence deposit) for increasing retention capacity regarding the solids contained in the feed water

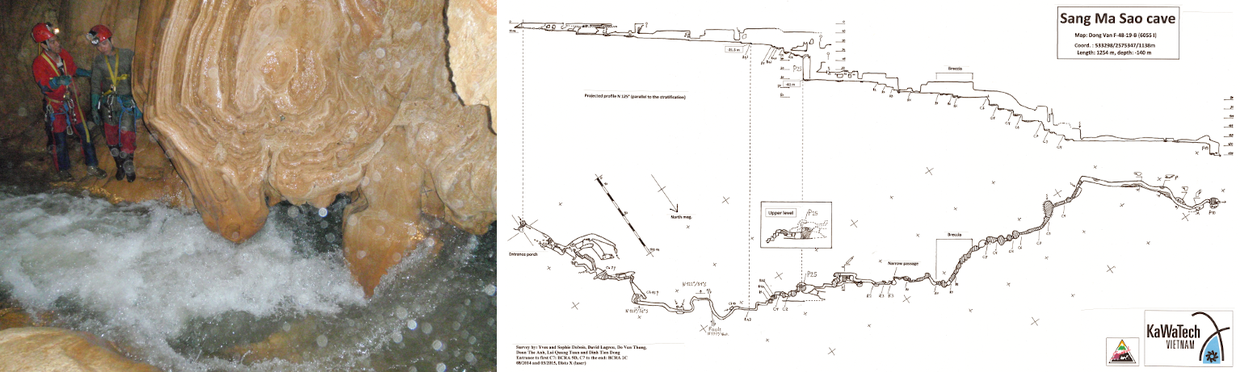

Innovative Water Pumping Technologies (Pumping Concept 2)

Concept study on enclosed pumping modules with an energy generation and a water pumping unit for decentralized use under extreme physiographical conditions (e.g. in difficult-to-access karst caves and mountain streams).

The physiographical conditions (e.g. large runoff fluctuations, occurrence of extreme hydrodynamic forces and morphodynamic processes of the river basin system) can significantly hinder the utilization of hydroelectric potential to pump water (left), case study using Sang Ma Sao karst cave as an example (right)

Building Materials Technology Experiments / Customized Construction Methods

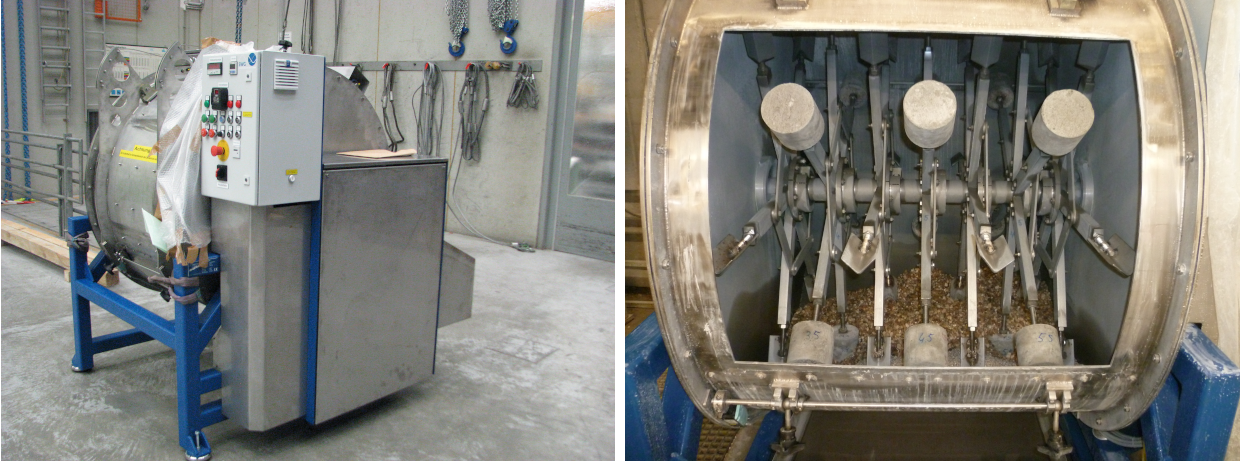

Inter alia, construction and building of an innovative testing facility for hydroabrasion processes as well as the development of hydroabrasion-resistant concrete types for hydro-engineering plants while utilizing raw materials available in the region.

Development of an innovative testing facility for hydroabrasion processes ("Karlsruher Verschleißtrommel 2.0") (links), realistic abrasion tests on small concrete specimens based on locally available raw materials (right)

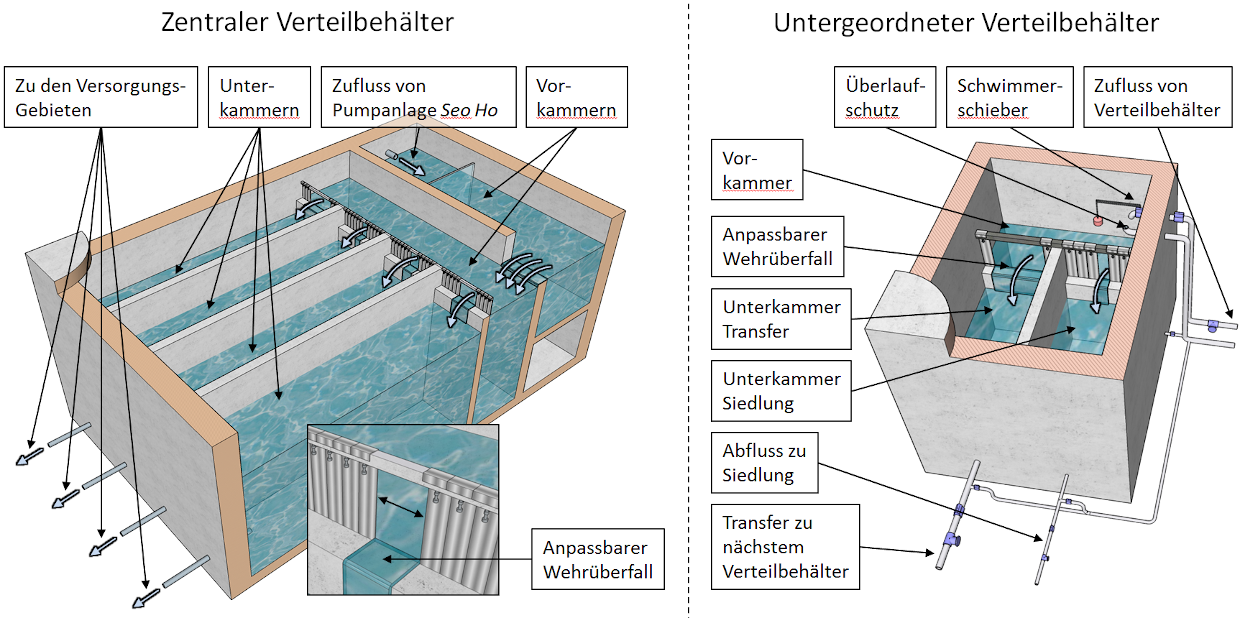

Water Distribution Concept

Development of a customized distribution concept for fair distribution of a limited amount of water independent of the users' location in the service area as well as implementation of initial distribution infrastructure in the project region.

Central distribution tank with innovative multi-chambered system to fairly distribute the amount of water pumped among the connected service areas (left), subordinate distribution tank to further distribute the amount of water among the settlements within the service area (right)

Construction of the central distribution tank beside a school in Ma U village

Monitoring / Measurement Technology

Development and construction of an off-road, online particle system, inter alia, for water quality monitoring for the protection of the pilot water pumping plant implemented according to Pumping Concept 1 from abrasion through solids contained in the feed water.

Development of an online particle measurement system for off-road use (manufacturer: Markus Klotz GmbH; model: PCSS Fluid Light)